Eleca®

- TOP

- Eleca®

Effect of Eleca

Electrolysis technology

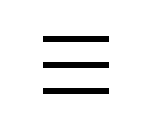

・Treats ammoniac nitrogen, COD and BOD in wastewater.・Contributes to improving the adsorption efficiency and extending the life of activated carbon by decomposing and reducing the molecular weight of water-soluble organic matter.

・Decolorization (Decoloration) of wastewater.

・Deodorising wastewater.

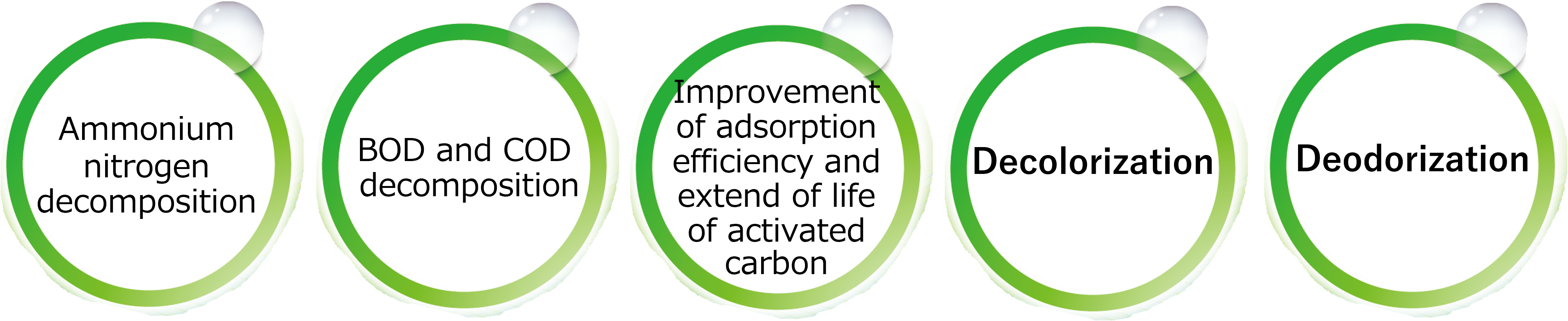

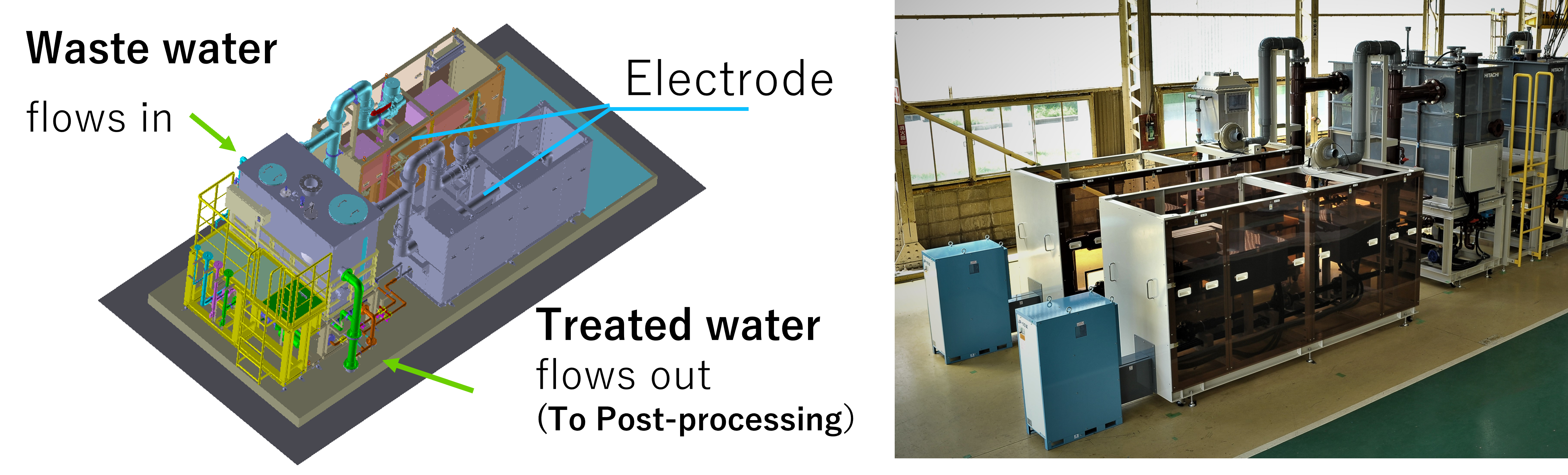

Eleca equipment flow(Smaller space than microbiological treatment)

Specification of Eleca

Specification

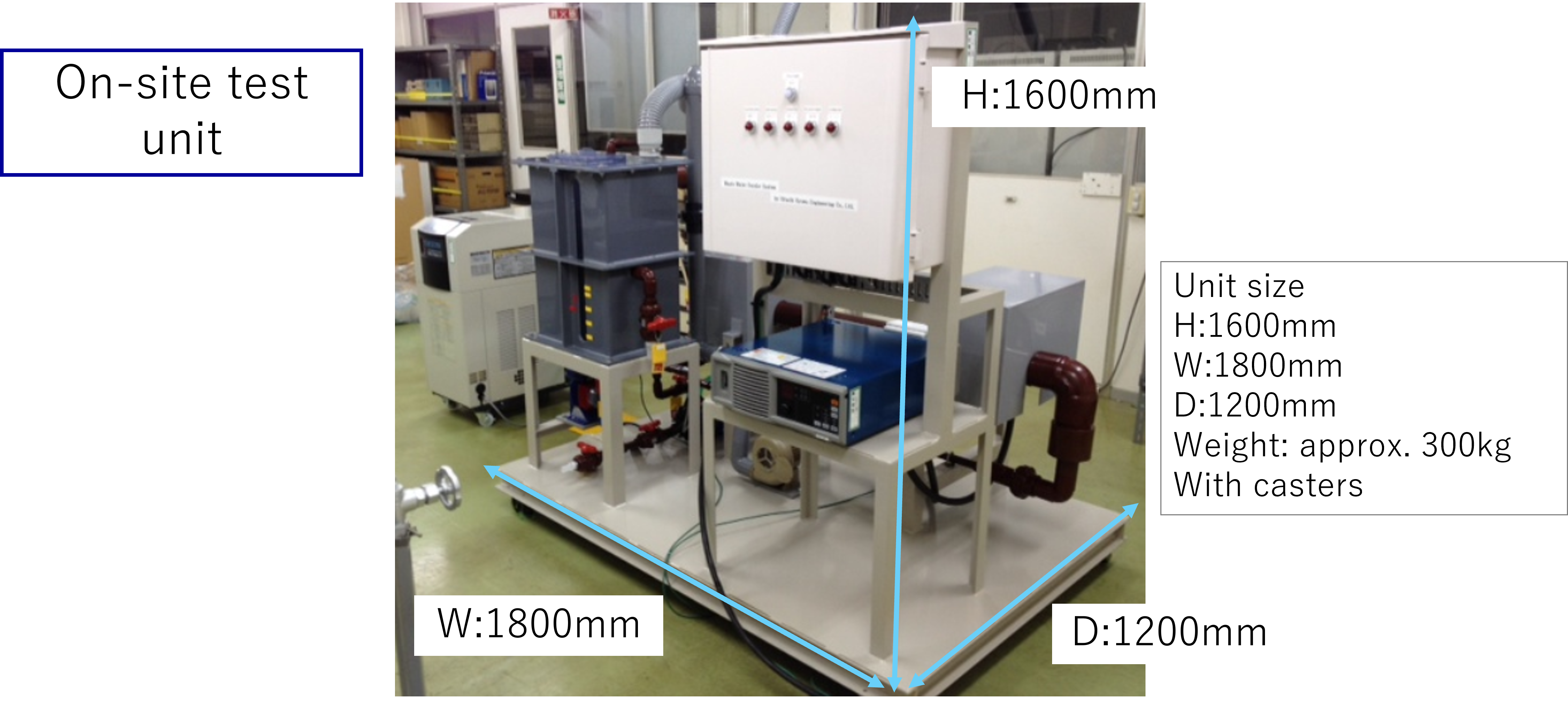

| Eleca® | Eleca® mini | |

| Equipment size | H :2,600 mm W:6,000 mm D:3,000 mm | H :1,795 mm W:2,825 mm D:1,500 mm |

| Equipment Weight | About 6,000 kg | About 1,000 kg |

| Ammonia nitrogen treatment capacity | Approx.100m3/day. The condition to reduce ammonia nitrogen from 200mg/L to 10mg/L or below |

Approx.5m3/day. The condition to reduce ammonia nitrogen from 200mg/L to 10mg/L or below |

| Amount of wastewater to be treated | N-fold Eleca to match the volume of wastewater | N-fold Eleca to match the volume of wastewater |

Features of Eleca

Stabilization

The process is stable in all seasons and weather conditions.Simple operation management

Operation is only ON/OFF.Reduces the burden on facility managers.

Small space

Layout flexibility for any installation location.Supports replacement of existing equipment and facility expansion.

No sludge

Electrolysis uses chemical reactions to break down and treat target components.No sludge or other waste is generated,

making the equipment both operational and environmentally friendly.

Highly durable electrodes produce active oxygen

Over the years we have developed electrodesthat efficiently generates reactive oxygen species

and are excellent in corrosion resistance.

The electrode replacement life is low, contributing to lower operating costs.

*compared to our company’s product

Eleca case study

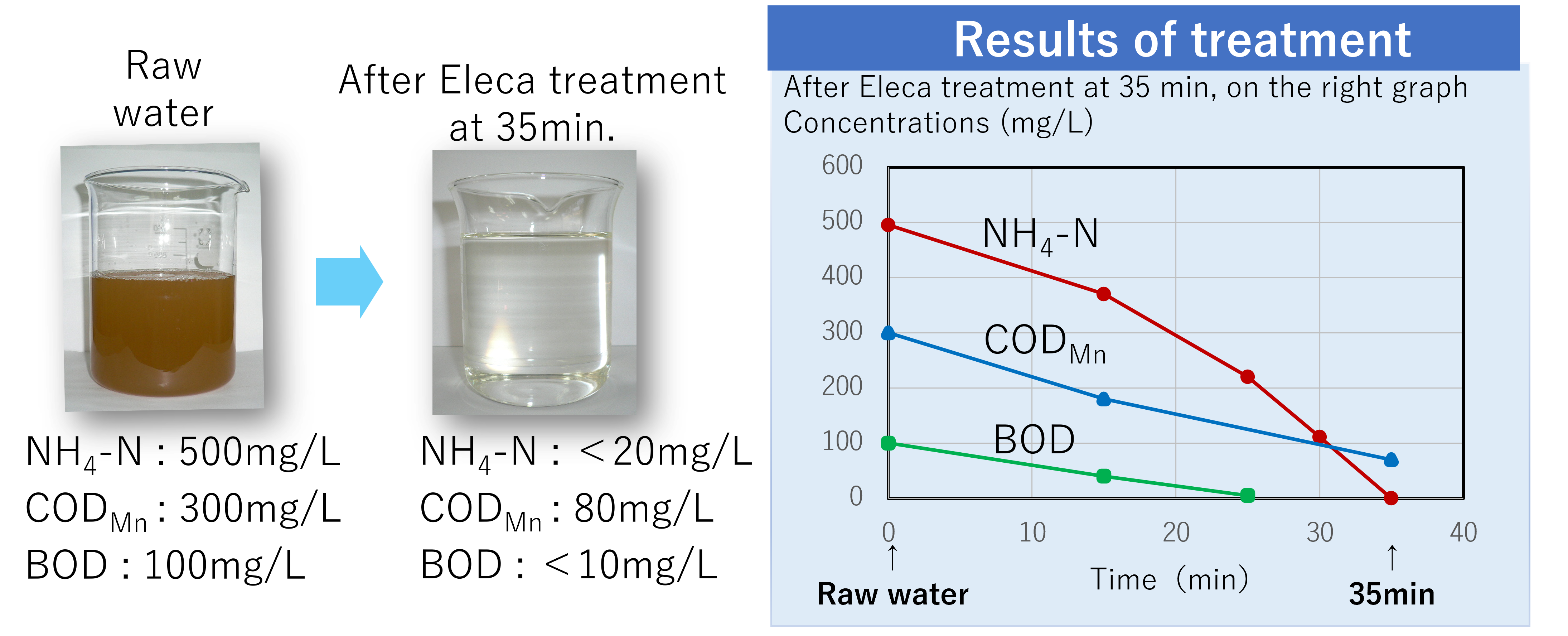

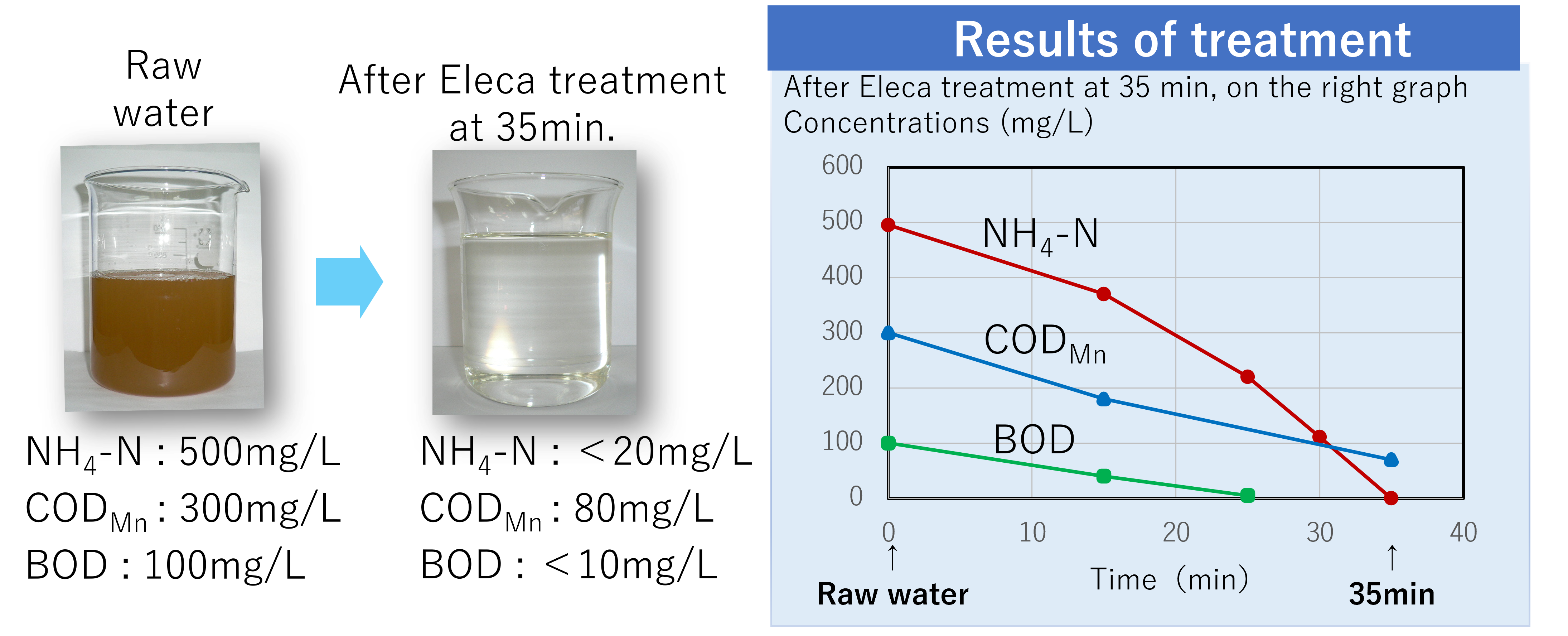

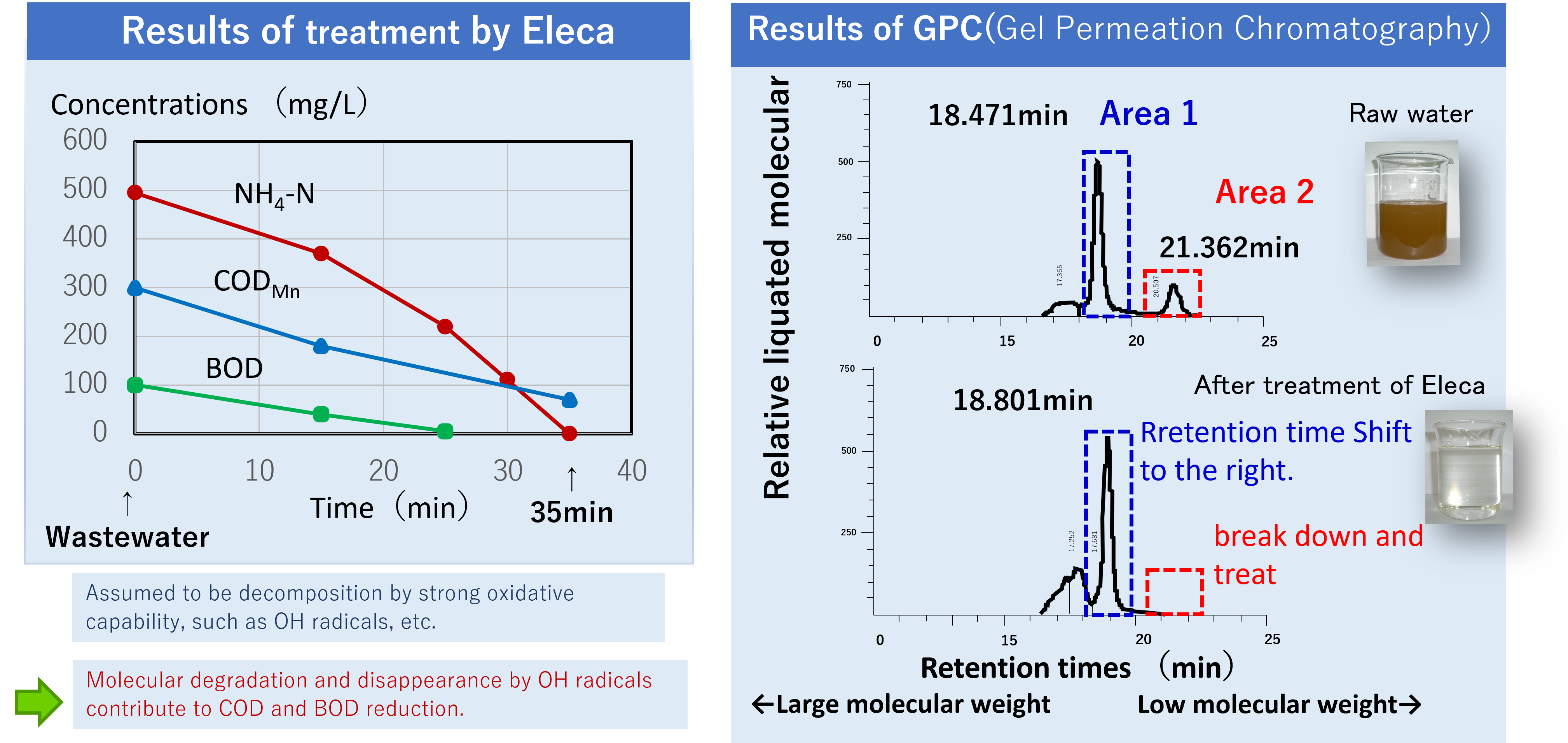

Kind of wastewater:controlled landfill leachate.

Feature :containing NH4-N and component of COD and BOD, etc.

Feature :containing NH4-N and component of COD and BOD, etc.

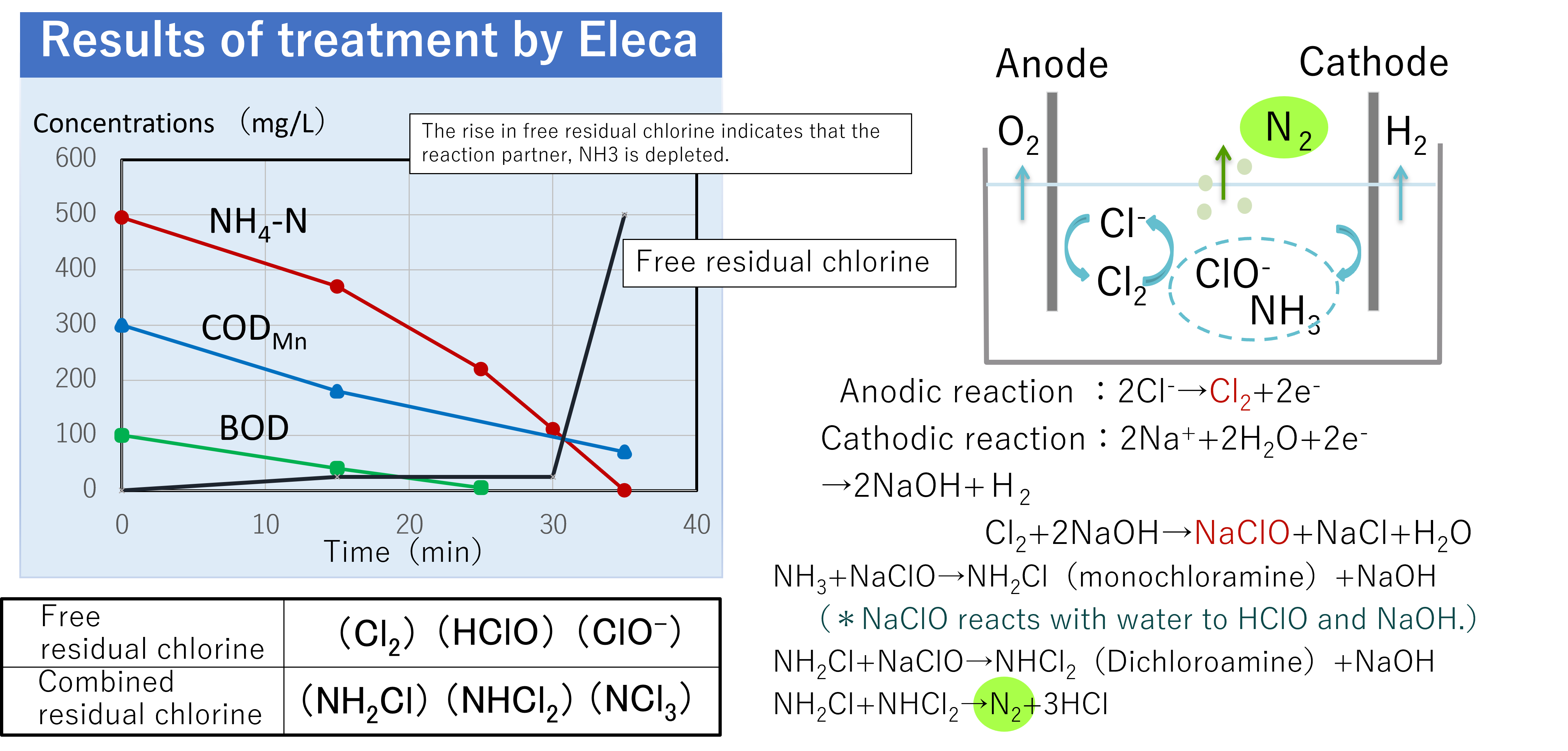

About NH4-N decomposition reactions

Decomposition of BOD and COD components

Effects of decomposition of COD and BOD components

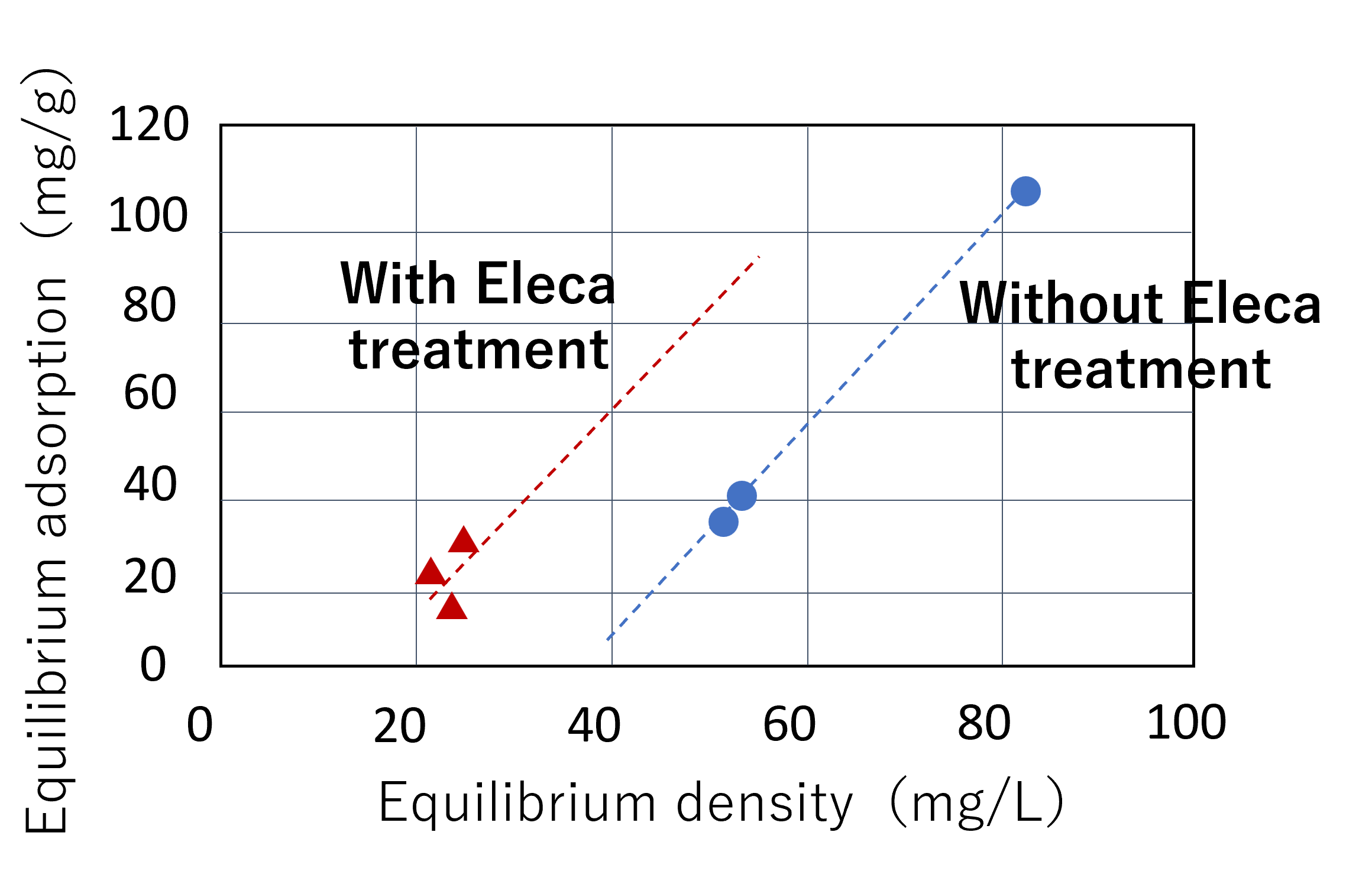

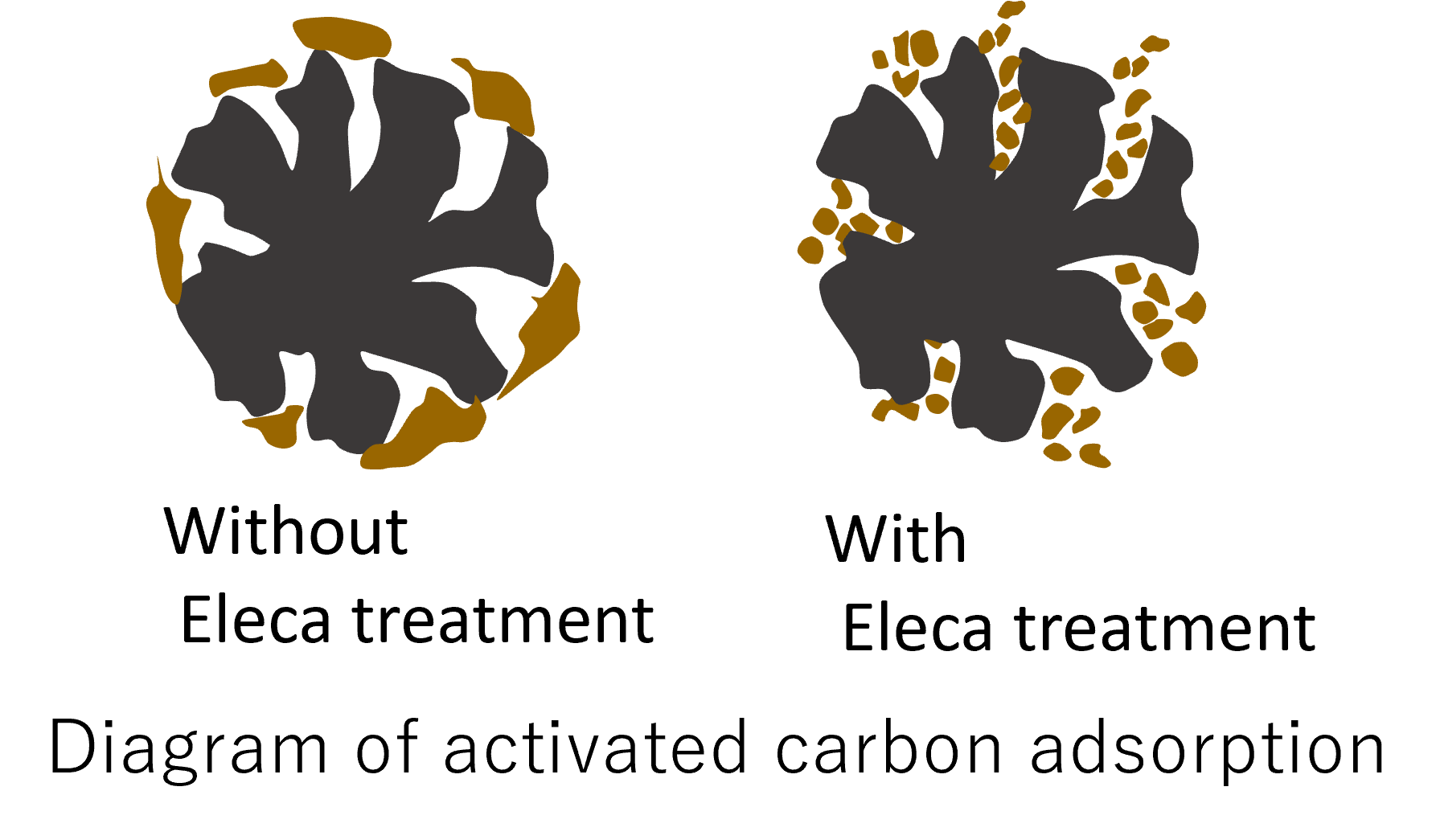

Increased activated carbon adsorption efficiency and life extention

-

Equilibrium adsorption: Amount of CODMn adsorbed on activated carbon per gram

Equilibrium density : CODMn content after reaction of samples with activated carbon -

The higher the equilibrium adsorption at the same equilibrium concentration, the more effectively the activated carbon pores are used.

Case study

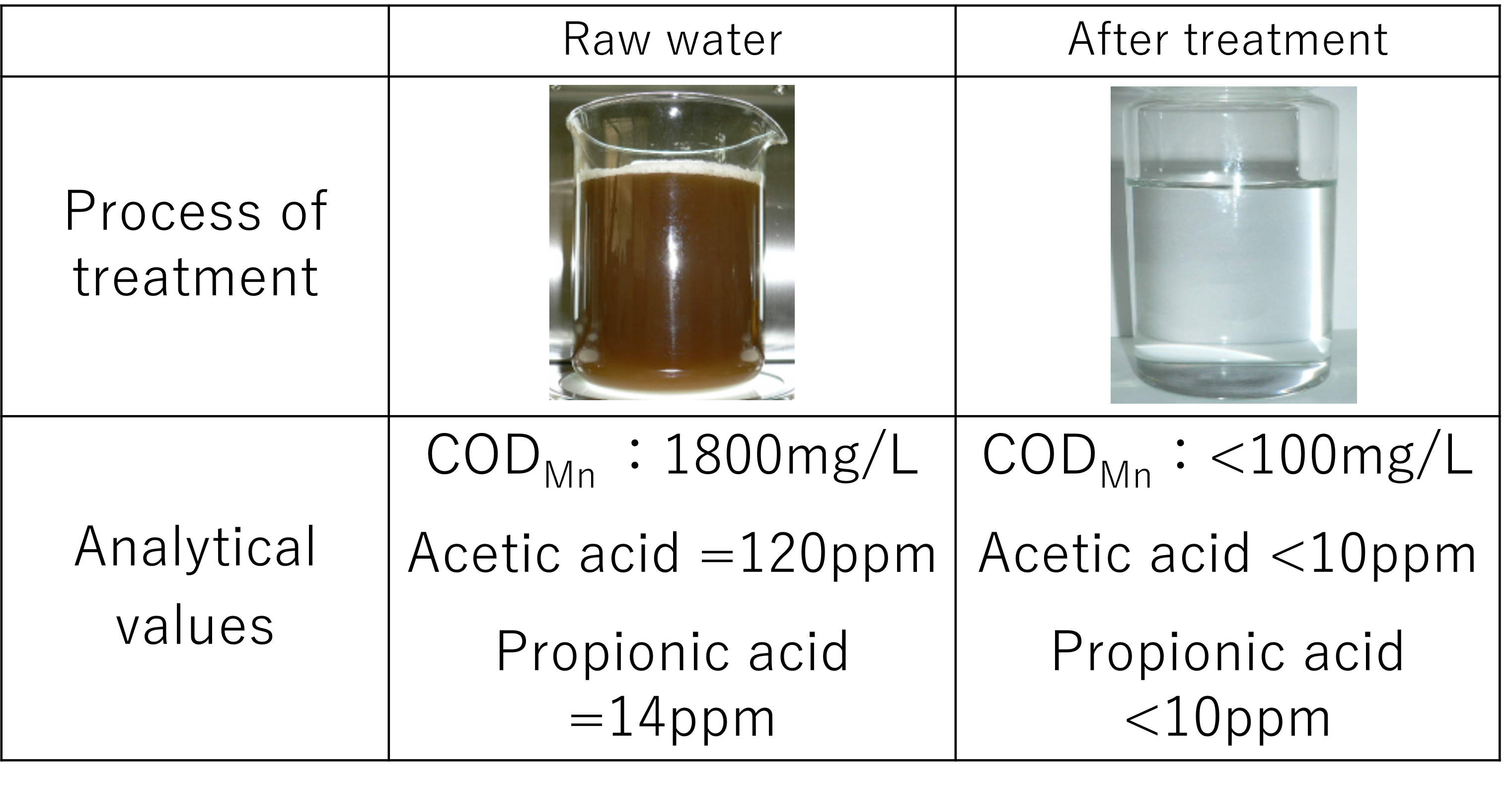

case 1:Oil-containing wastewater

Wastewater: Produced water from oil field.Problem : Acetic acid and propionic acid cannot be treated with flocculants.

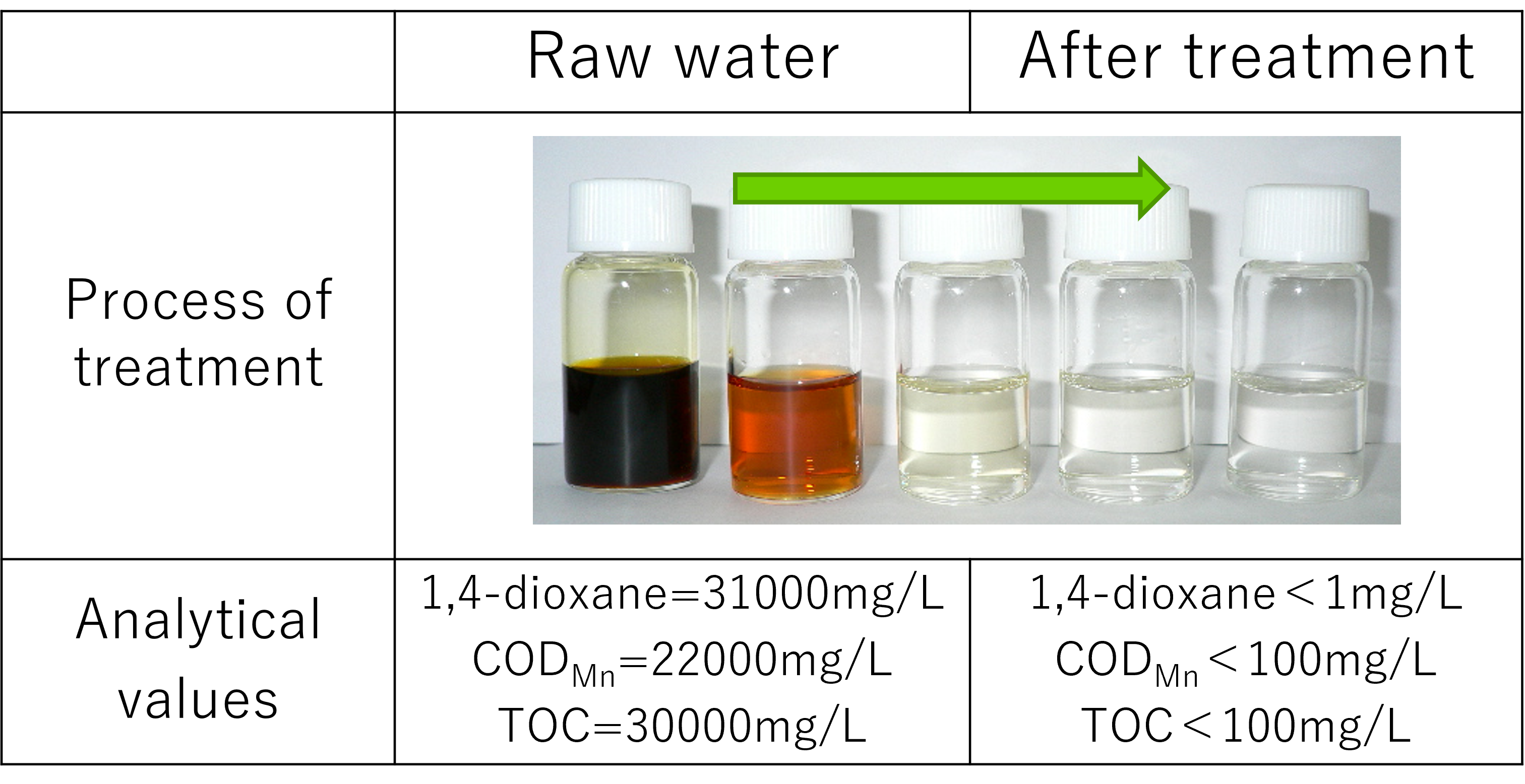

Case2: Chemical wastewater

Problem:1,4-dioxane is persistent substances and have difficulty in treatment.

Case3 Chemical wastewater

Problem:Although various treatment techniques were taken, the color does not fade.

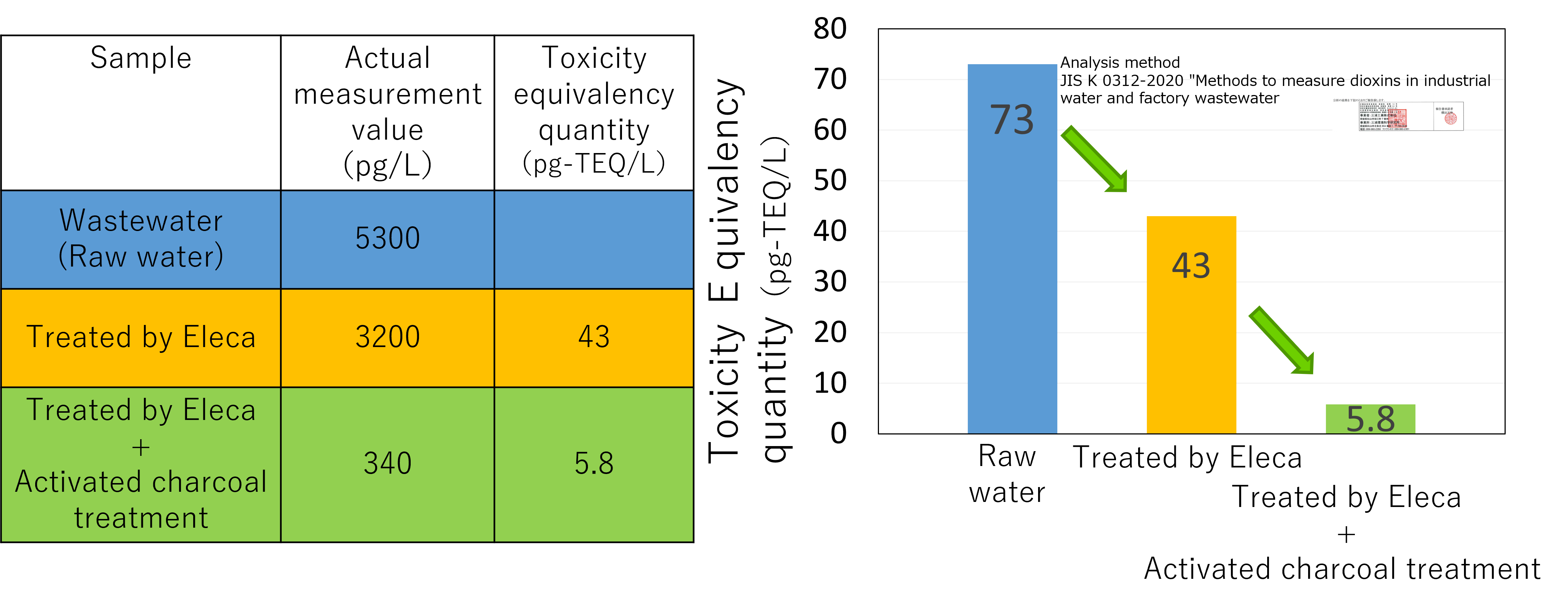

Case 4 About Dioxin

Dioxins are persistent substances that are hardly degraded in the natural environment.The ratios of incineration and combustion get higher as the effluent sources of dioxin.

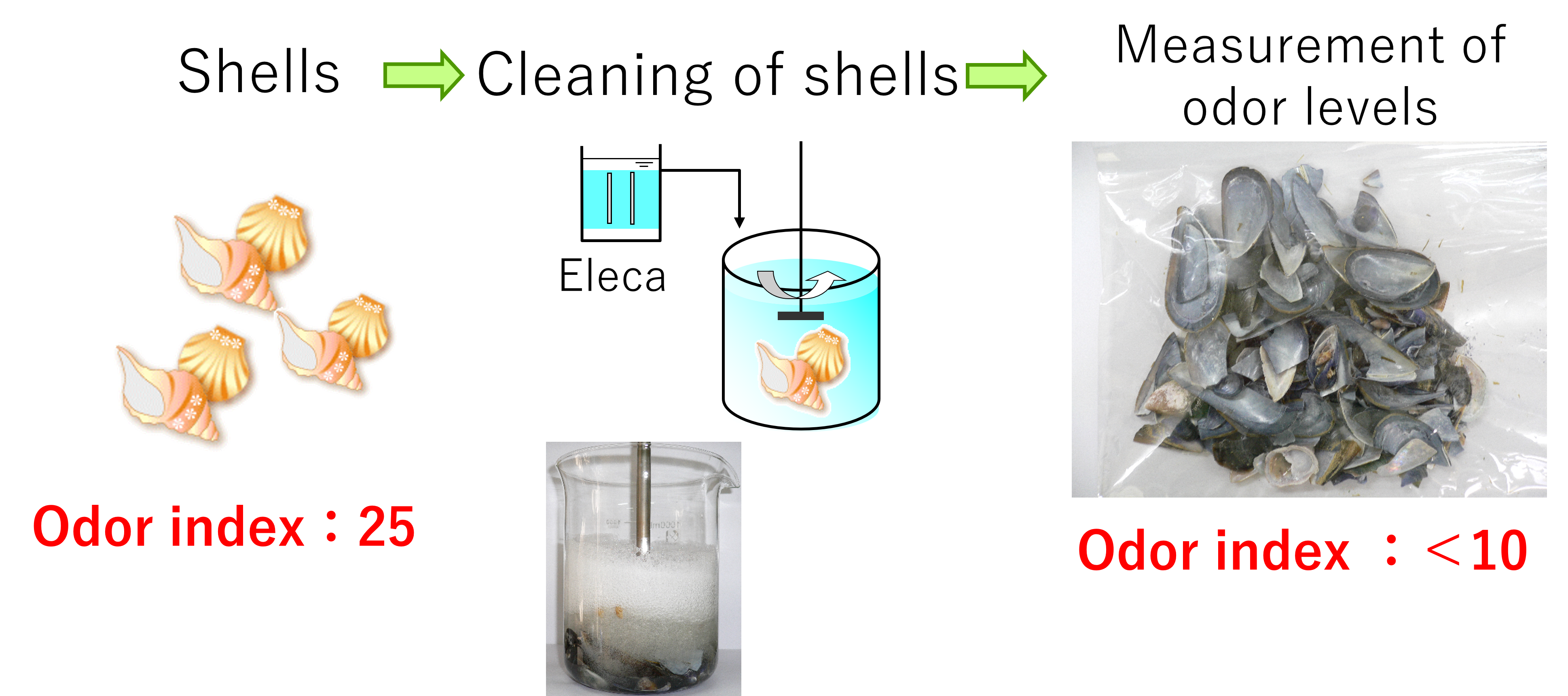

Case5 Odor control of shells

Problem:Odor problems with shells collected at ports, etc.

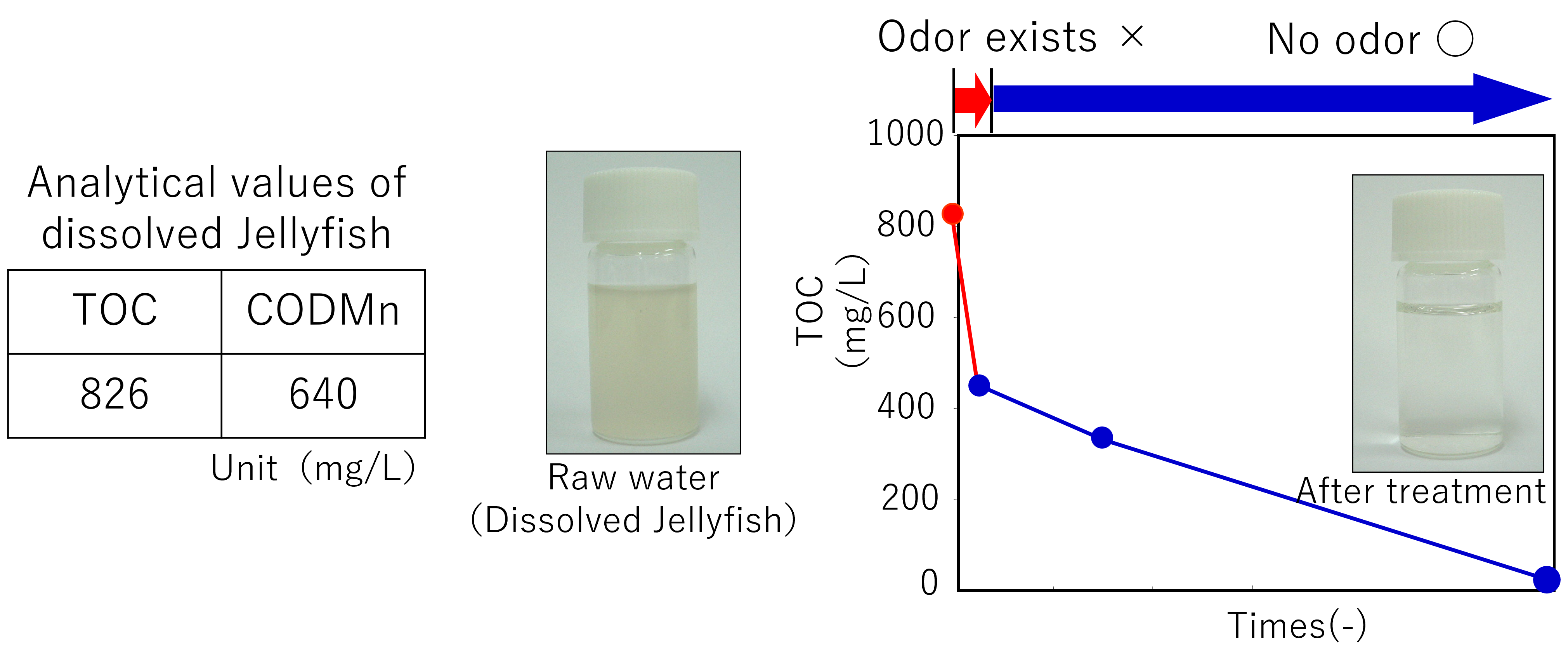

Case6 Jellyfish Odour control and decomposing

Problem:Decomposing of collected jellyfish at seawater intake for cooling.

Proposal of Eleca system

System examples

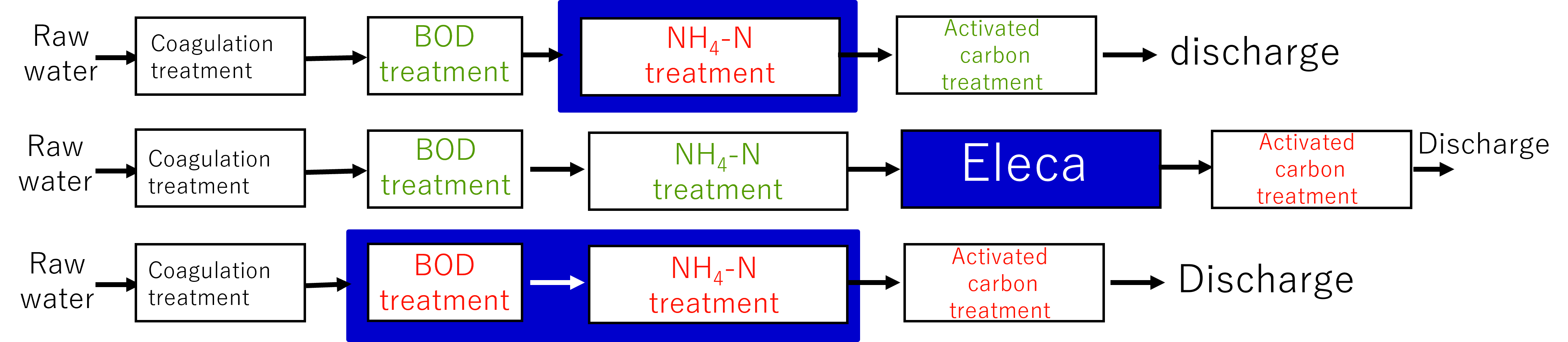

▮Normal system configuration

*Some treatment facilities are omitted.

▮System constitution example by Eleca

Reduction of the load of biological treatment and activated carbon treatment.

*An example of the system is introduced above. We will propose the best system for you according to types of wastewater.Delivery record

H Co., Ltd.(Fukushima)Installation of 3 Eleca units

Other achievement

・D Co., Ltd.(Hirosima)Installation of 2 Eleca units・Under the demonstration test before installation:1

Contact us

We will propose the best Eleca for you according to your condition of wastewater.

STEP1

Please feel free to contact us.

Laboratory tests are conducted using actual wastewater.

Test can be tested with approximately 5L wastewater.

Based on the test results, volume of the equipment (number of Eleca units) and operating costs will be proposed.

Please consider installation of Eleca.

If you need on-site testing, you can check it with a on-site test unit.

Please feel free to contact us.

▼

STEP2Laboratory tests are conducted using actual wastewater.

Test can be tested with approximately 5L wastewater.

Based on the test results, volume of the equipment (number of Eleca units) and operating costs will be proposed.

▼

STEP3Please consider installation of Eleca.

If you need on-site testing, you can check it with a on-site test unit.